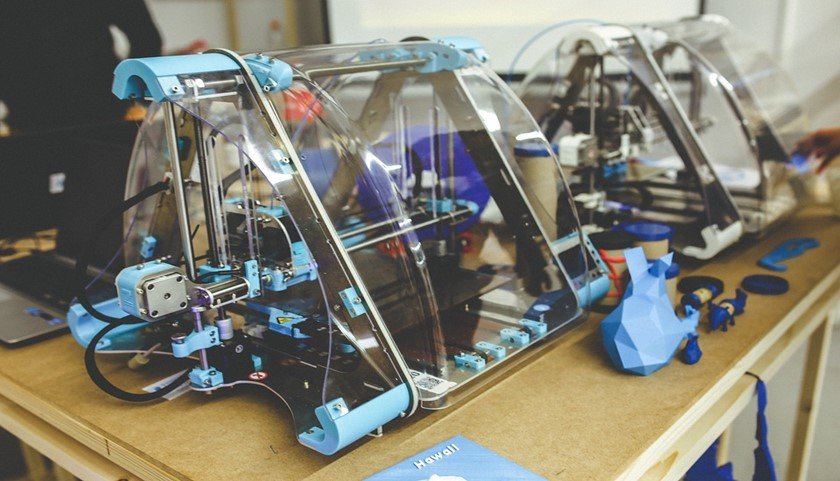

3D printing is a process that use automation to build 3-dimensional objects from a digital blueprint or model. When choosing 3D printing over the traditional manufacturing methods, you have to look at its pros and cons to know whether it is right for you.

Pros:

1. Rapid Prototyping: A 3D printer offer rapid prototyping which allows you to quickly design, produce, and test a customized part and quickly modify the design without affecting the speed of the printing process.

2. Freedom of design: 3D printing allows you to produce complex geometry that is difficult to make with traditional manufacturing methods. You can easily modify your designs and make any type of geometry.

3. Reduce waste: 3D printing use additive manufacturing process where the only material used is the one needed to produce the part required. Traditional machining method cuts large chunks of non-recyclable material to produce the part resulting in a lot of waste.

4. Cost: Due to reduced wastage of material, 3D printing results in reduced cost of production since you only pay for the material required to print.

5. Print on demand: 3D printing enables you to print on demand and avoid overstocked and costly inventory. It uses a Just-in-time inventory management technique to free-up inventory space by printing designs only when needed and in the exact volume required.

6. Speed: 3D printing can print parts in just a few hours depending on the complexity and parts size as opposed to machining which can take longer.

7. Offer more manufacturing options: 3D printing method has provided a wide array of manufactured products. It can produce personal designs and customized products.

8. Lighter: 3D printing uses a plastic material which is much lighter than the metal counterparts. Many automobiles use 3D printed parts that make their vehicles lighter and fuel efficient.

9. Saves on warehousing cost: 3D printing only manufacture products on-demand therefore, you don’t have to worry about storage space or having a warehouse for excess inventory.

10. Creates more jobs: A wide use of 3D printing will result in the creation of jobs to engineers to design the devices and technicians who will maintain the inventory as well as fix problems. More artist will rely on the use of 3D printing to deliver their products.

Cons:

1. Not suitable for large volumes: If you need to produce a large number of parts, then 3D printing is not an ideal production process. Other methods like injection molding can be cost-effective for printing large parts.

2. Limited materials: Only specific plastics with certain mechanical properties can be used to produce parts in 3D printing. Some few 3D printers can work with metal which also has a limited selection.

3. Limited build volume: Most of the 3D printers have small build chambers and if you have a printing part larger than the build printer chamber then the parts have to be divided into sections which are later glued together during post-processing.

4. The increased cost of large printing parts: If you have larger printing parts than the build chamber, it will increase the printing cost since it takes a longer time to print the parts. The process also needs manual labor.

5. Reduce manufacturing jobs: 3D printing will lead to reduced manufacturing jobs and this will have an effect in third-world economies especially those which rely on low-skill jobs.

6. Copyright issues: More use of 3D printing mechanisms will lead to a lot of copyright issues. It will open doors for more counterfeit products especially if the product exists in a digital file.

7. Post processing: 3D printing need clean-up to remove the support material and smoothen the surface of the parts produced. This slows down the process.

8. Creation of dangerous items: 3D printing can lead to the production of dangerous items like guns and counterfeit money if no proper regulation. The production process can also undermine control mechanisms.

9. Printing useless items: 3D printing can lead to manufacturing of useless items which are not environment-friendly.

10. Part structure: In Additive manufacturing process, parts are printed in layers which must adhere to one another during the printing process. If the layers separate, then the parts break.